Did you know they are not the same thing?

Did you know they are not the same thing?

Did you know, technically, there is no such thing as an Egress Window?

While it is common to refer to the required Emergency Escape and Rescue Opening (EE&RO) in a bedroom or basement as an egress window, it is not the correct terminology. You will not find the term “egress window” in the residential building codes.

2018 IRC R310.1 Emergency escape and rescue opening required. Basements, habitable attics and every sleeping room shall have not less than one operable emergency escape and rescue opening. Where basements contain one or more sleeping rooms, an emergency escape and rescue opening shall be required in each sleeping room. Emergency escape and rescue openings shall open directly into a public way, or to a yard or court that opens to a public way.

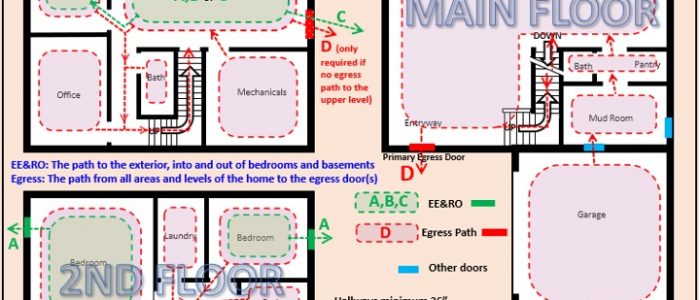

Egress is the required path from all portions of the building, including each floor level, to the required egress door—and only one is required. The required egress door must meet certain size requirements, be side-hinged, and can’t have a dead-bolt keyed on both sides (among other requirements). Other doors “can” meet these requirements but are not required to.

2018 IRC R311.1 Means of egress. Dwellings shall be provided with a means of egress in accordance with this section. The means of egress shall provide a continuous and unobstructed path of vertical and horizontal egress travel from all portions of the dwelling to the required egress door without requiring travel through a garage. The required egress door shall open directly into a public way or to a yard or court that opens to a public way.

R311.2 Egress door. Not less than one egress door shall be provided for each dwelling unit. The egress door shall be side-hinged, and shall provide a clear width of not less than 32 inches (813 mm) where measured between the face of the door and the stop, with the door open 90 degrees (1.57 rad). The clear height of the door opening shall be not less than 78 inches (1981 mm) in height measured from the top of the threshold to the bottom of the stop. Other doors shall not be required to comply with these minimum dimensions. Egress doors shall be readily openable from inside the dwelling without the use of a key or special knowledge or effort.

It is important for all building occupants to familiarize themselves with this exit/egress path in case of emergency. Other doors to the exterior might not exit to a space that could be escaped from, like a fenced-in backyard, or even a balcony or deck with no stairs.

The Escape and Rescue openings also have size requirements designed such that emergency personnel can get in and persons within the building can get out in an emergency. These EE&RO requirements are typically met with windows, but they can be doors as well. The doors used for EE&RO do not have to meet Egress requirements–they could even be as small as the required window.

All the spaces in a basement require egress to the primary egress door, or it could meet this requirement with its own egress door if that door opens to a public way. Opening into the backyard of the home would not meet this requirement. Since most basements have stairs to get to them, the stairs can meet the requirement for egress if of proper width and construction. Remodeled basements often have problems with proper egress.

All habitable basement spaces require Emergency Escape and Rescue Openings as well. This can be met with a proper window or door in the basement space (the door would not have to meet the requirements of an Egress door). It can also be met with the window or door in an adjacent basement bedroom.

The following diagram shows in red/pink the pathways from areas of the home to the egress door, and in green the areas that require emergency escape and rescue openings.

Old habits die hard, and correct terminology is important.

By Charles Buell, Real Estate Inspections in Seattle

If you enjoyed this post, and would like to get notices of new posts to my blog, please subscribe via email in the little box to the right. I promise NO spamming of your email! 🙂